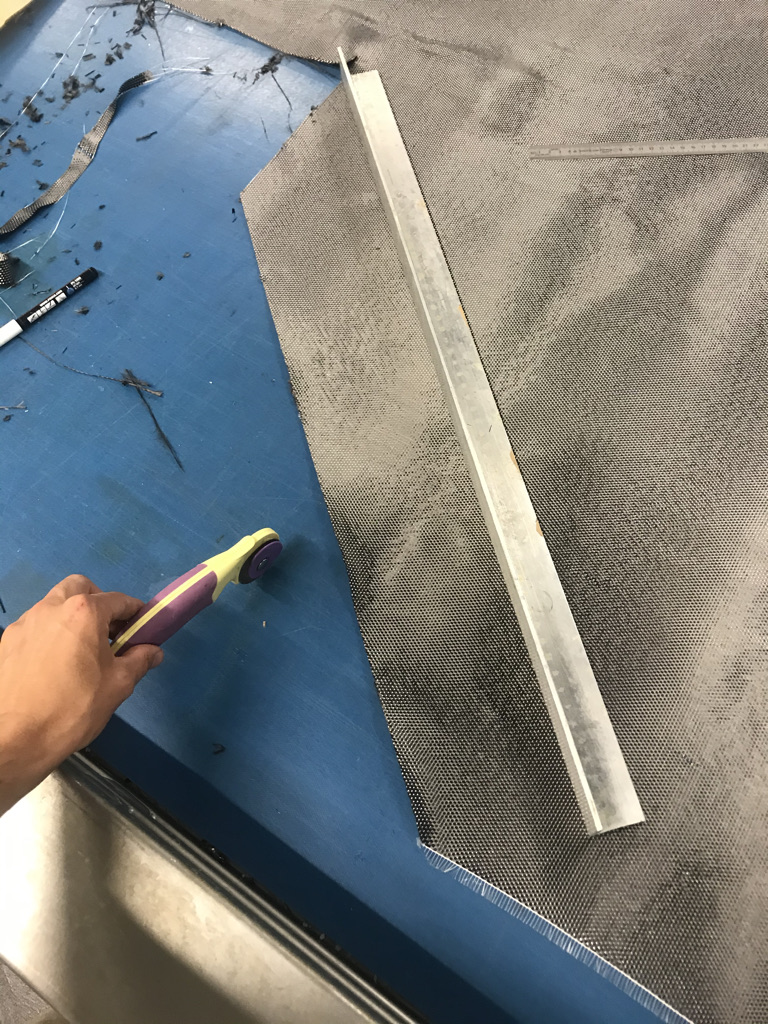

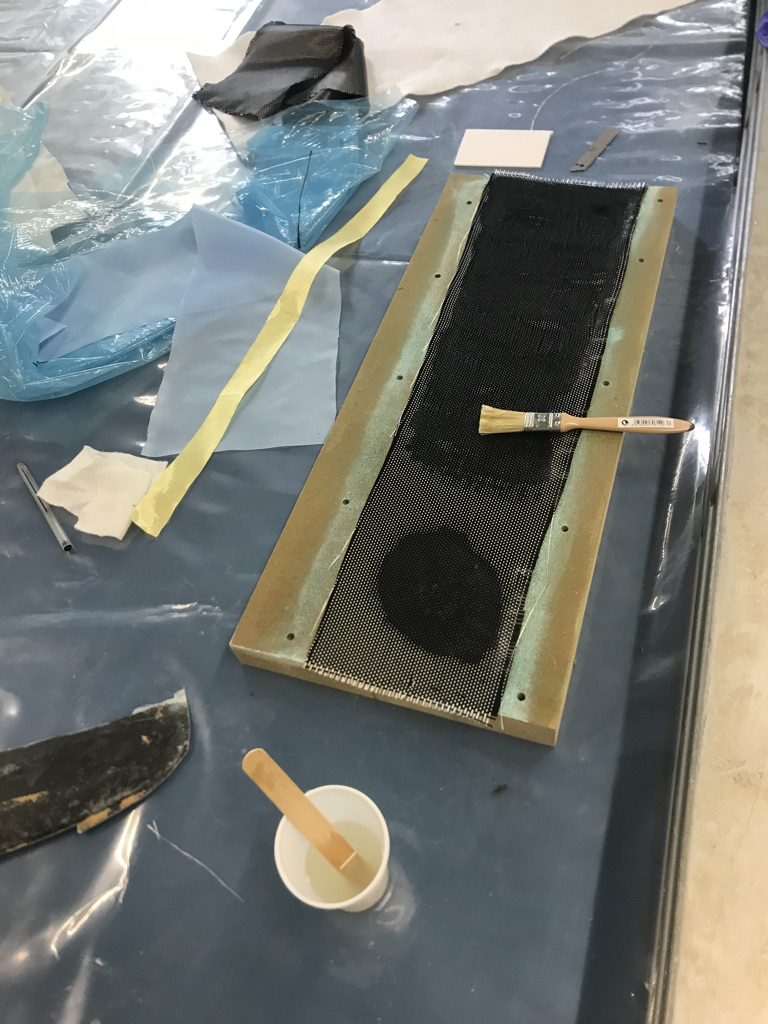

Laying up

Each side of the wings were made of two layers of 170g/m^2 carbon. One layer in the direction of the wing the other with a 45° offset in order to resist to torsion

The goal is to have 60% of carbon mass with 40% of resin. I always put 50% of resin and let the tissues absorb the excess when in the vaccum

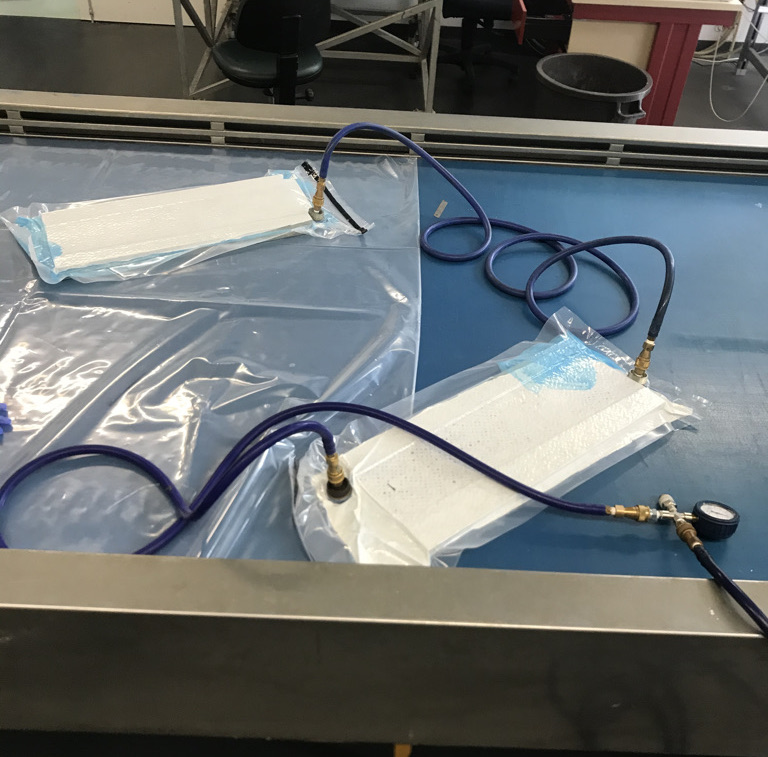

Vaccum

I was able to use all the tools Supaero's research department of structures had (DMSM). The Vaccum was one of those tools I could use.

Its goal was to force the carbon to have exactly the same shape as the mold and to absorb the excess of resin

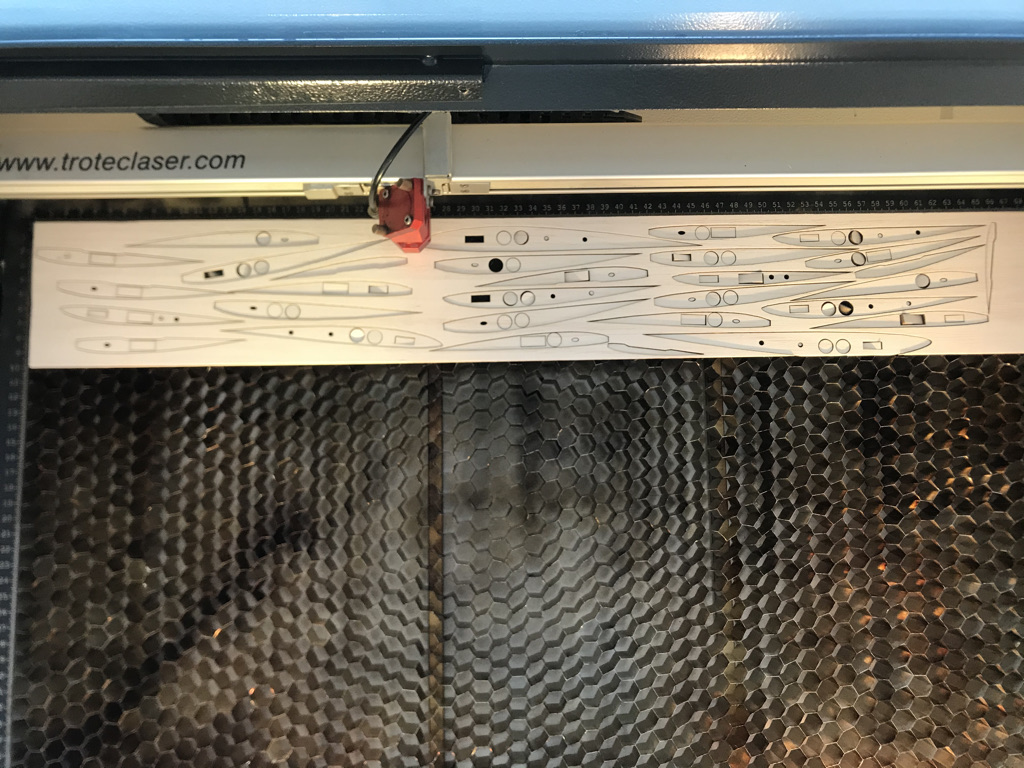

Cutting the ribs

With the Fablab's laser cut I could cut the ribs precisely. I chose to have each rib cut in two different wood: one in balsa and the other in Tilleul. I then glued them together before gluing them in place i the wings and fuselage

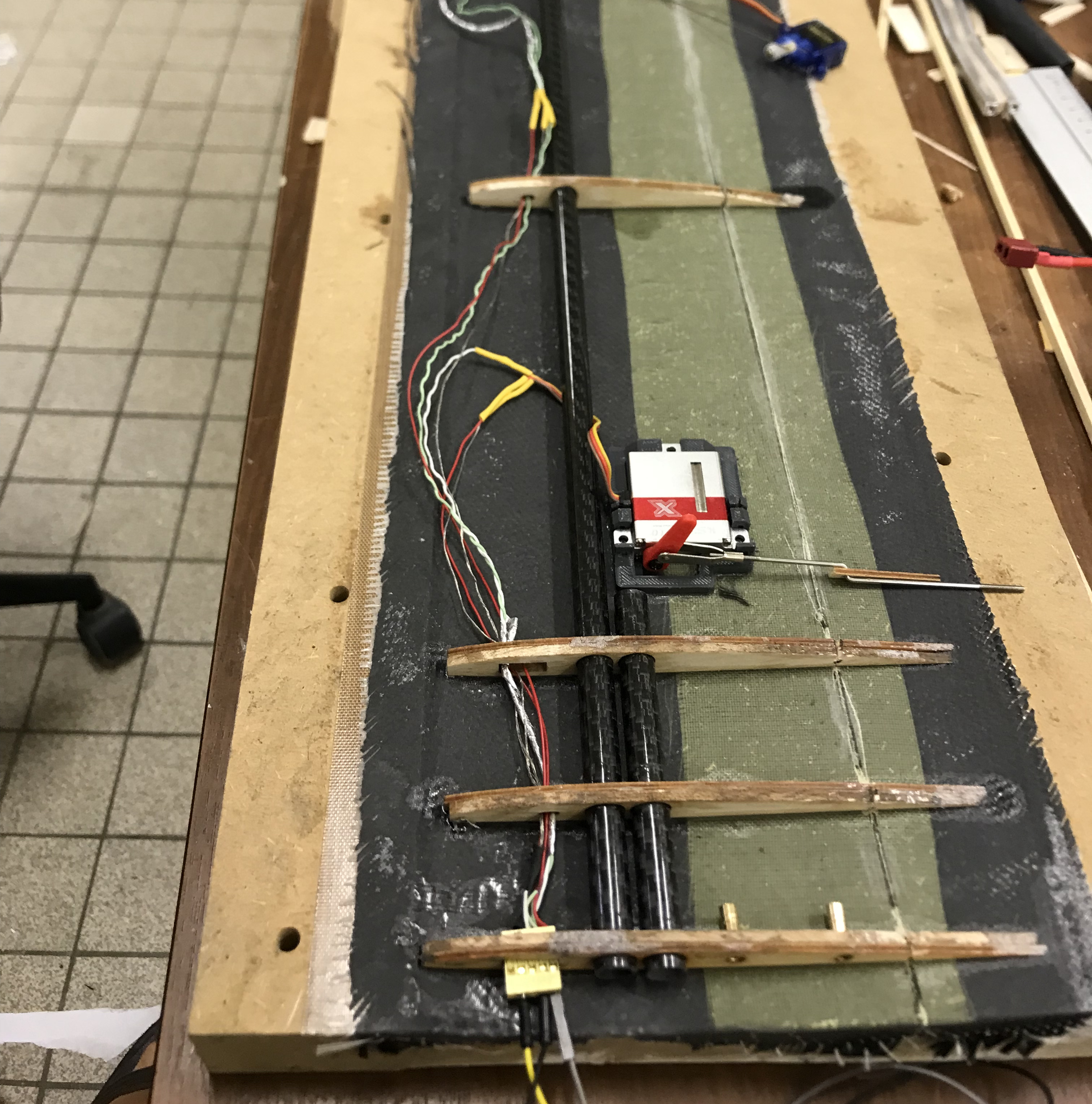

Installing the commands

Inside the wing I had to add all the servos, all the mechanical and electrical connections, all the hinges (made of kevlar) for the ailerons and flaps, all the ribs etc.

This was a part I thought would take much less time than it did. I didn't want any commands to appear when the wing was closed and I think this was a mistake it took me so much effort just for this.

I was however pleased with the electrical connections: when the wings are joined together the electrical coinnction is automatic, no need to connect dozens of cables, and that is the spirit of HIKO: it needs to be very fast and easy to be ready to launch !